Calibration

By Calibration of pressure switch it means to make the pressure switch sets and resets at desired pressure . pressure switch calibration is done for sensing either a ‘pressure low’ condition or ‘pressure high’ condition.Both calibration slightly differs from each other .It is important to note the requirement .ie we should know what is the pressure switch function in our application. ie PSH , pressure switch high or PSL , pressure switch low .ie weather it has to be calibrated for ‘low ‘ condition or for ‘high’ condition .It is important because a pressure switch calibrated to use for high condition may not be used for low condition or vice versa unless it is recalibrated .

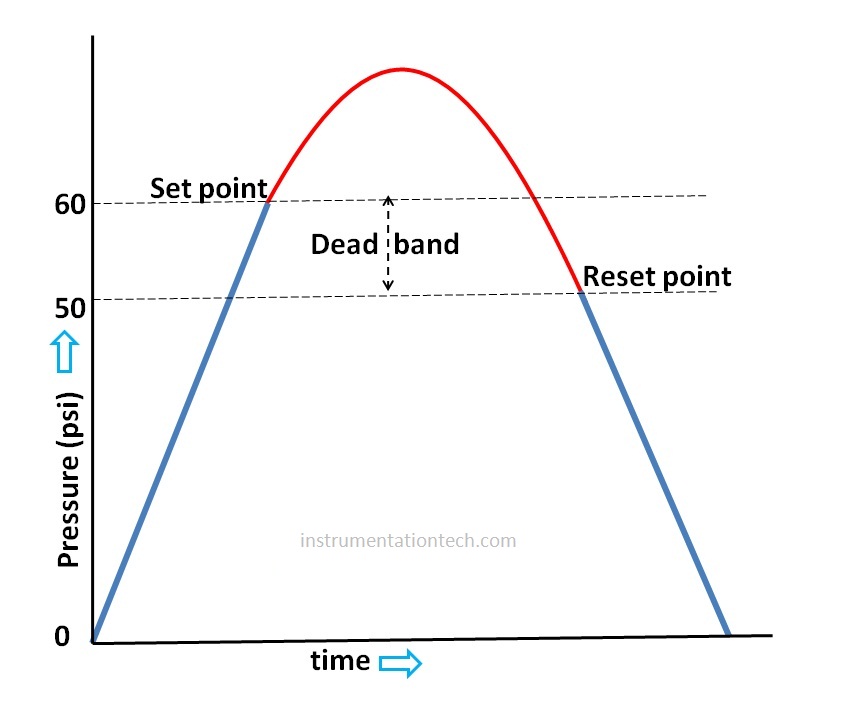

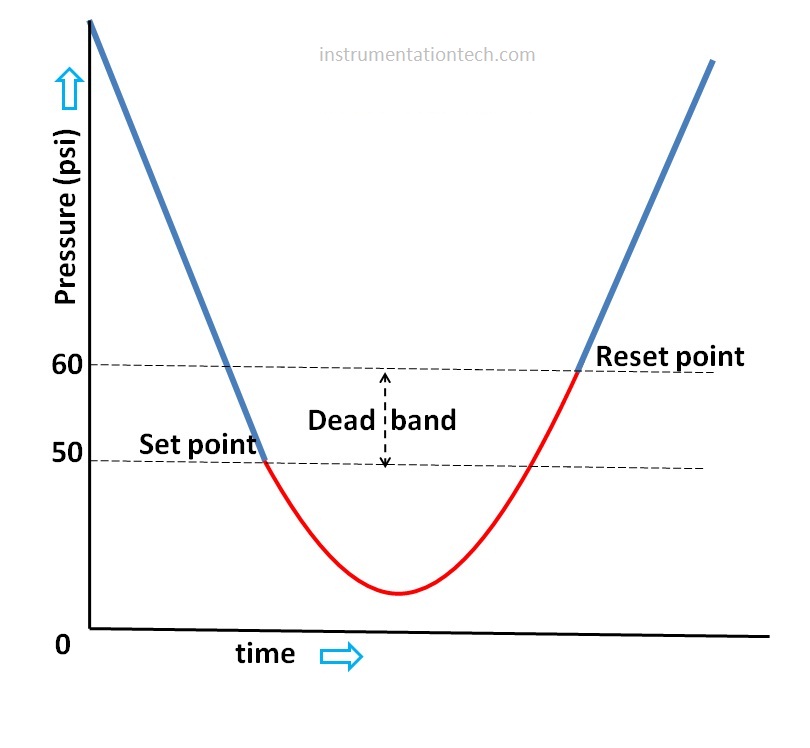

For example a pressure switch calibrated for high alarm at a setpoint 60 psi with a dead band of 10 (Means reset at 50 psi) .It cannot be used as a low sensing switch at the same setpoint 60 psi . But it can be used as a low sensing switch with a setpoint 50 psi and reset point 60 psi. So the setpoint and reset point got interchanged as we change the function of pressure switch .

Obviously calibration procedure for’ pressure switch low’ and ‘pressure switch high ‘ is different .Though only a small difference but an important one .

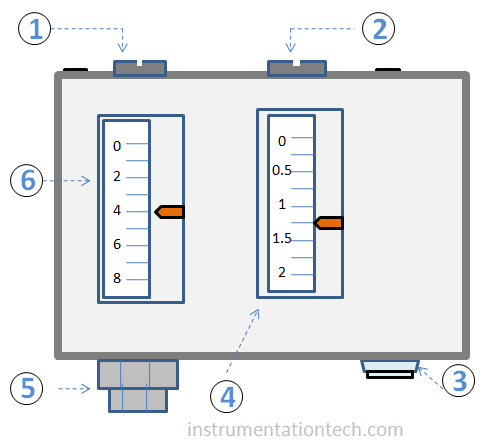

1.Setpoint adjusting nut

2.Dead band adjusting nut(Reset point)

3.Cable entry

4.scale- Dead band(Reset point)

5.pressure connection

6.Scale -Setpoint

Equipments and materials needed

Pressure source

Multimeter

Standard Master pressure gauge or digital pressure indicator

Connecting wires, tube fittings

Tools required

Adjustable spanner

Screw driver

Most of the pressure switch are provided with graduated setpoint and dead band scale . setpoint and dead band can be adjusted with the the help of this scale and through the knobs provided . But the adjustments through this scale will be not so accurate .we has to calibrate the pressure switch by applying pressure and adjusting the setpoint and dead band through corresponding knob or screw or whatever the provision employed in pressure switch .

calibration for 'pressure high' setpoint

Aim

Calibrate a pressure switch for a pressure high condition at 60 psi with a dead band of 10 psi

Here our aim is to calibrate a pressure switch which change its contact status at 60 psi on increasing pressure and resets at 50 psi (dead band 10 psi ) after attaining setpoint.

See the above diagram .It represents the response of pressure switch contacts with increasing and decreasing pressure .The blue line indicates the pressure switch is in reset condition .And red line indicates the pressure switch in set condition.

calibration set up

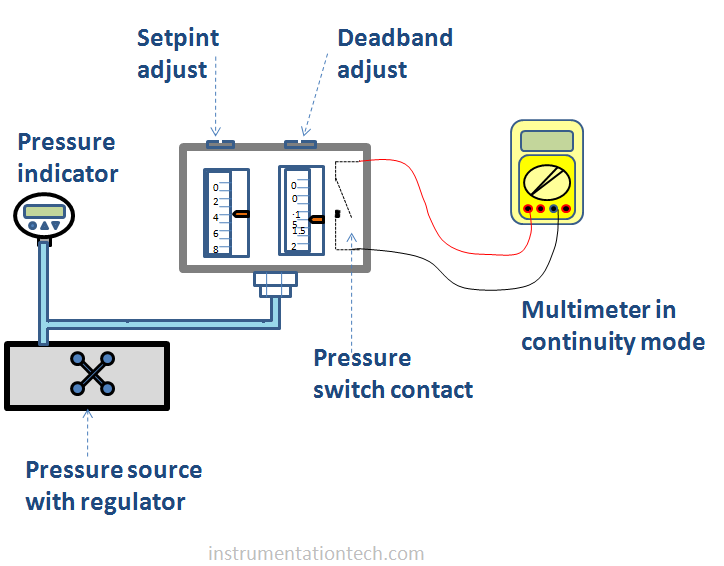

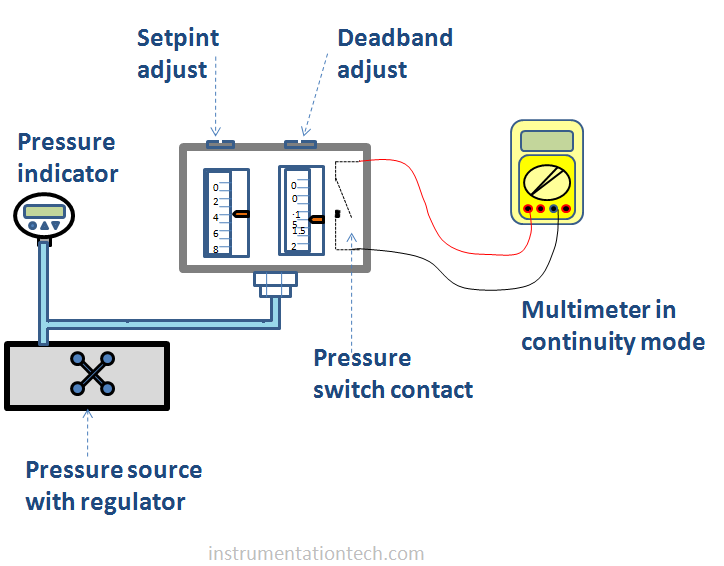

Connect a pressure source with regulator to the pressure connection port of the pressure switch.

Also Connect a digital pressure indicator with required accuracy if the pressure source is not provided with the indicator .

Connect a multimeter to contact terminals of the pressure switch.you can opt NO or NC with common terminal.Here we are using NO and COMMON

See figure.

calibration procedure for 'high 'setpoint

1.check the NO ,NC terminals of pressure switch with multimeter .

NO should be open while no pressure applied to pressure switch .

NC should be close when no pressure applied to pressure switch.

If it is not adjust the setpoint knob two three turns to get the required status of the pressure switch when there is no pressure .

2.Increase the pressure slowly and note the value of pressure at which contact status changes. (NO contact changes to to close) .This is the present setpoint of the pressure switch and we need to adjust this point to 60 psi.Turn the setpoint adjustment knob properly to increase or decrease the setpoint.turn one or two .

5.Decrease the pressure and note the point at which the pressure switch resets(CLOSE Changes back to NO) .This point is the reset point . The desired reset point we need at 50 psi.adjust dead band adjusting knob to increase or decrease the Reset point.

Repeat the steps 4 and 5 to get the set and reset point at 50 and 40 psi respectively

Note:. inorder to get the results more accurately ,adjusting the knob have to be done finely as we approaches the setpoint and reset point .

calibration for 'pressure low' setpoint

Calibrate a pressure switch for a pressure low conddition at 50 psi with a dead band of 10 psi

Here our aim is to calibrate a pressure switch which change its contact status at 50 psi on decreasing pressure and resets at 60 psi (dead band 10 psi ) on increasing pressure after attaining setpoint .See the below diagram .It represents the response of pressure switch contacts with decreasing and increasing pressure .The blue line indicates the pressure switch is in reset condition .And red line indicates the pressure switch in set condition .

The procedure is different from the previous case .Here we need to apply pressure initially well above the present reset point . And gradually decrease the pressure and check the point at which pressure switch sets . Do Adjustments on pressure switch setpoint and dead band knob .

calibration procedure for 'Low' setpoint '

1 .Check NO,NC terminals of the pressure switch .

NO should be open while no pressure applied to pressure switch .

NC should be close when no pressure applied to pressure switch.

If it is not, adjust the setpoint knob two three turns to get the required status of the pressure switch when there is no pressure .

2.As we are calibrating for a low condition ,(50 psi )pressure switch is considered as set condition when it is opened to atmosphere or when no extra pressure applied .

Increase the pressure and allow the pressure switch to reset .(in our case we need this point at 60 psi) . and note the value of pressure at which contact status changes. (No changes to to close) .This is the present reset point of the pressure switch and we need to adjust this point to 60 psi.Turn the dead band adjustment knob properly to increase or decrease the resetpoint.turn one or two .

5.Decrease the pressure and note the point at which the pressure switch sets(close changes back to no) . The desired reset point we need at 50 psi.adjust setpoint adjusting knob to increase or decrease the setpoint .

Repeat the steps 4 and 5 to get the set and reset point at 50 and 60 psi respectively .

Note:. inorder to get the results more accurately ,the degree of rotation of the adjusting the knob have to be done finely as we approaches the setpoint and reset point .