In process plant ,parameters like flow, temperature,level, pressure etc have to be controlled as per requirement . various sensors and devices are used to measure these variables . And to control, final control elements are used such as valves,motors,pumps ,Heaters etc.

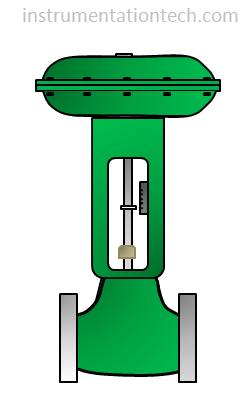

Control valves is one such item .They controls the flow of fluid passing through a stream by restricting the flow path by proper mechanism like plug and seat arrangement .

A device to regulate the flow of fluid through the pipeline by applying and varying the flow restriction through its body part .It acts as a final control element in a process stream . It is a key component of the process industry.it may be either pneumatically operated. or electrically operated , hydraulically operated etc .These pneumatic or electrical signal cause the valve to stroke to the required position thereby varying the flow restriction in its body through which fluid flows .

Control valves being a part of process control loop generally operated remotely or from control room (Through DCS or PLC or any other control system or controller.)

There are lots of types like,on/off valves, Butterfly valves , solenoid operated valves .Also there are lots of classification based on body type, action, actuating mechanism etc .

Linear and rotary motion valves

Ex: Linear :Valves with linear actuator.

rotary valve : butterfly valve ,Ball valves.

Based on Actuating medium:

pneumatically operated,electrically operated ,hydrollically operated

Based on Body type:

Globe,Ball valve, butterfly valve .

Failsafe condition

Normally open

Normally close

Valves which are operated in analogue mode like that with pneumatically operated diaphragm actuators are generally referred as control valves .A range of pressure is needed to operate this valve in 0–100% position .