pressure switch

Compressor control

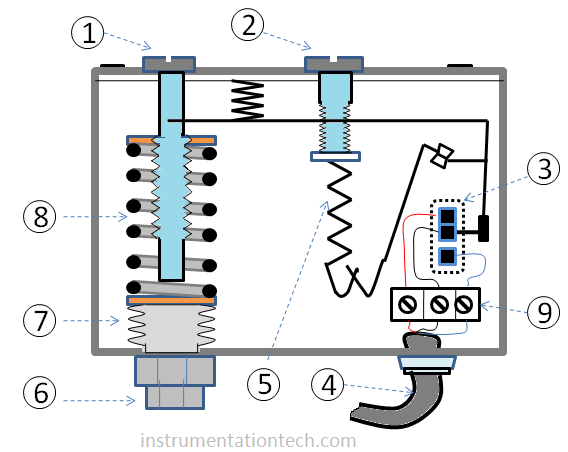

The pressure acting on the sensing element is transferred to a mechanical assembly .And this mechanical assembly is linked to a micro switch .So the applied pressure causes make or break its contacts at some desired setpoint thereby allowing the control circuit open or closed .And the desired operation can be obtained through the control circuit .

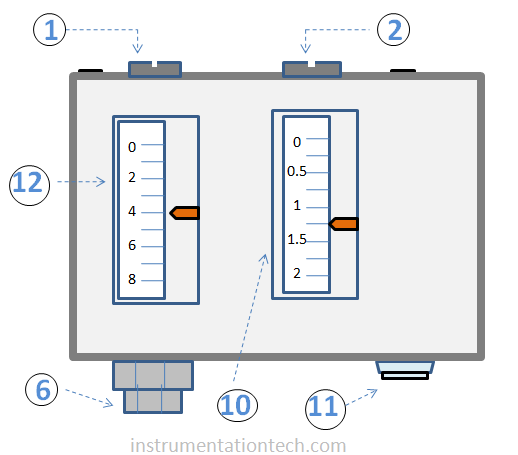

components

1.Setpoint adjusting nut

We can adjust setpoint by increasing or decreasing the tension on this range adjusting spring .Or setpoint adjusting spring.The movement of mechanical links is the net result of this tension on the spring and the force on the bellows due to the pressure acting .So we can adjust the setpoint by changing this spring tension through its knob

2 .Dead band adjusting nut

Dead band of the pressure switch can be adjusted by changing the tension of another spring .The dead band is the difference in value of pressure between setpoint and reset point .The mechanical links in the pressure switch is so constructed such that once it change its status on applying a specific value of pressure ,it doesn’t regains it’s previous status at the same point on reversal of the pressure signal . It allows a specific band of pressure through which it stays at the new status .Only after that the pressure switch returns to previous status .This is done by properly constructed linkages and spring.The spring tension can be adjusted to get the required dead band .

3.Microswitch

It is a small switch assembly which operates by means of mechanical movement caused by the pressure . The micro switch is properly linked to the mechanical assembly.It consists electric contacts which makes or breaks at the setpoint and reset points accordingly .

4.electrical connection

Cable entry will be provided the pressure switch inorder to make electrical connections .one can make connections in the provided NO,NC,COMMON contacts through proper connecting terminals .

5 Dead band adjusting spring .

6 .Pressure connection

7 .Sensing element

The pressure is fed in to the sensing elements which in turn cause itself to make a mechanical movement proportional to the applied pressure .Bellows, Diaphragm, bourdon , etc are the common sensing elements used .The pressure applied to these elements cause it to expand transferr this movement to the links in the pressure switch

8 Setpoint. adjusting spring

9 .Connection terminals

10 .scale-Dead band

11 .cable entry

12. scale-setpoint

Terminal connection

The output of the pressure switch is a set of contacts which can be used for the desired control action .This contact outputs are connected to terminal connectors .

Scales for setpoint and Dead band

Scales may be provided to indicate setpoint and dead band .one can roughly calibrate a pressure switch by adjusting the setpoint and dead band with the help of this scale .But it is recommended to do the calibration by proper method.ie By applying pressure and adjusting the range and dead band to correct value .

Related terms

For’ pressure switch low’ reset point has a value above setpoint

PSH and PSL

Pressure switch can be calibrated to sense a pressure high condition or pressure low condition.

PSH

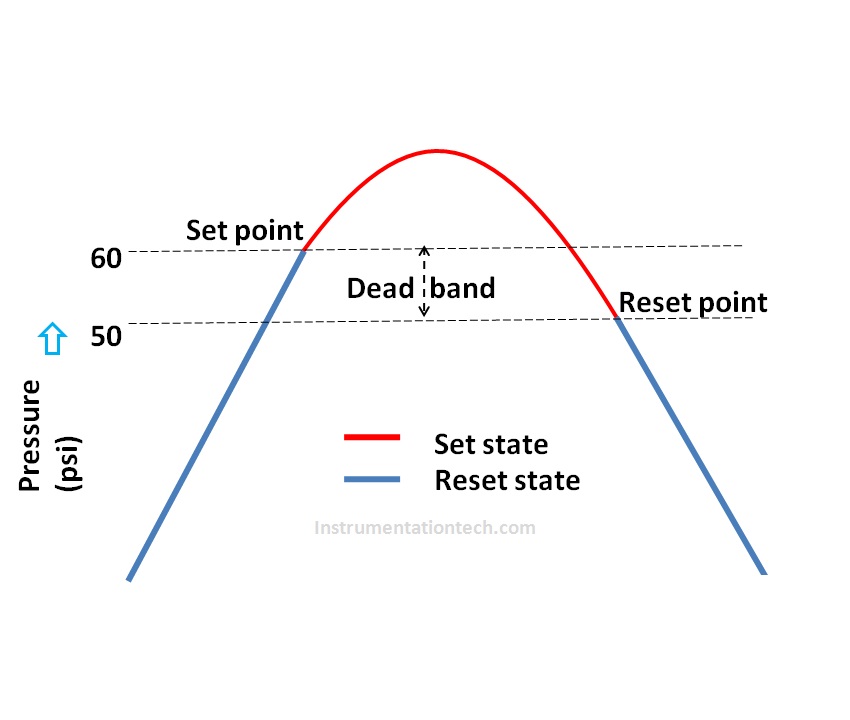

Suppose we want to activate an alarm or make a control action when pressure exceeds some predetermined value.This is achieved by calibrating a pressure switch for a pressure high condition Or PSH.

For example valve closes when pressure in pipeline exceeds the limit.

The below figure shows the variation of contact status of a pressure switch which is calibrated for Pressure high condition. Pressure is given to pressure switch from zero and increased and then decreased further.

We can see that pressure switch sets at 60Psi which is the set point which can be adjusted to a required value through the provision like knob or screw provided in the pressure switch.After pressure switch sets we decreased the pressure.Then what happens ? Does the pressure switch resets at the same pressure at which it sets??? No…The pressure switch resets at some other points below the setpoint. Called reset point. On examining the curve we can see that pressure switch sets at 60 on increasing pressure and after that on decreasing pressure it resets at 50 psi . The difference in gap between set point and reset point is the dead band of pressure switch .In this case 60 psi is the set point and 50 psi is the reset point and 10 psi ,the dead band .

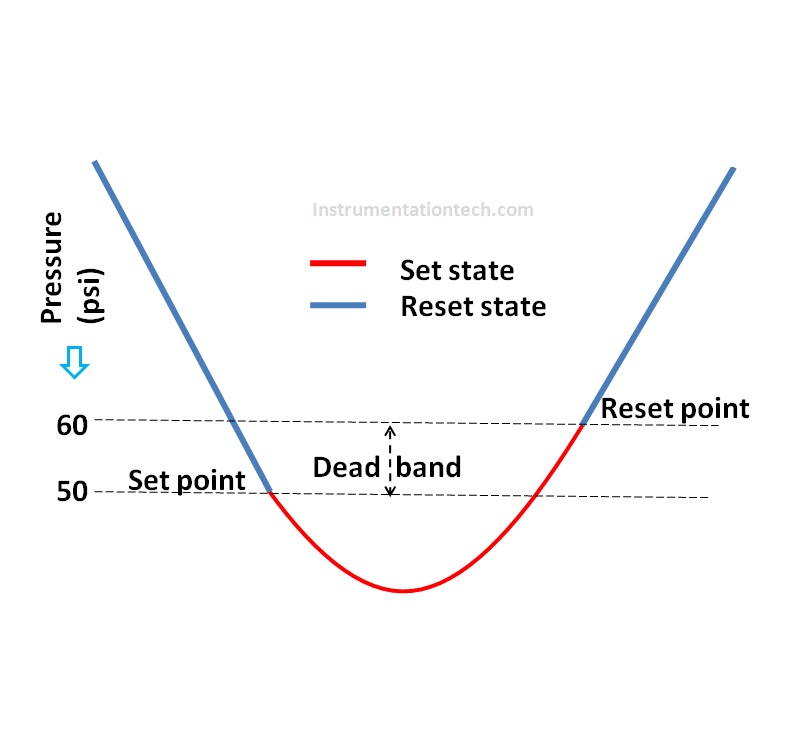

PSL- pressure switch low

Suppose we want to activate an alarm or make a control action when pressure falls below some predetermined value.This is achieved by calibrating a pressure switch for a pressure low condition Or PSL.

For example valve closes when pressure in pipeline falls below a specified value .

The below figure shows the variation of contact status of a pressure switch which is calibrated for Pressure low condition.

Pressure is given to pressure switch well above reset point and deceased and after reaching setpoint pressure is increased further.

On examining the curve we can see that pressure switch sets at 50 psi on decreasing pressure and after that on increasing pressure it resets at 60 psi . In this case 50 psi is the set point and 60 psi is the reset point and 10 psi ,the dead band.

Calibration

Calibration of pressure switch is make the pressure switch sets and resets at desired pressure..Pressure switch can be calibrated for sensing a‘pressure low’ condition or ‘pressure high’ condition.Both calibration slightly differs from each other .It is important to note the pressure switch function.ie weather it has to be calibrated for ‘low ‘ condition or for ‘high’ condition .It is important because a pressure switch calibrated to use for high condition cannot be used for low condition at the same setpoint .

a pressure switch calibrated for high alarm at a setpoint 60 psi with a dead band of 10 (reset at 50 psi) .It cannot be used as a pressure low switch for the same setpoint . .If it is to be used as a low switch the setpoint will be 50 psi and resetpoint will be at 60 psi.So in order to get a setpoint (for low) of 50 psi it needs to be recalibrated .

Obviously calibration procedure for’ pressure switch low’ and ‘pressure switch high ‘ is different .Though only a small difference but a critical one .